How to Choose the Best Industrial LED Fixtures for Your Business Needs

Choosing the right lighting for an industrial space is crucial for both operational efficiency and safety. As businesses increasingly turn to modern lighting solutions, Industrial LED Fixtures have emerged as a popular choice, thanks to their energy efficiency, longevity, and superior light quality. Whether you are upgrading existing lighting systems or fitting out a new facility, understanding the key factors in selecting Industrial LED Fixtures can significantly impact your bottom line and workplace environment.

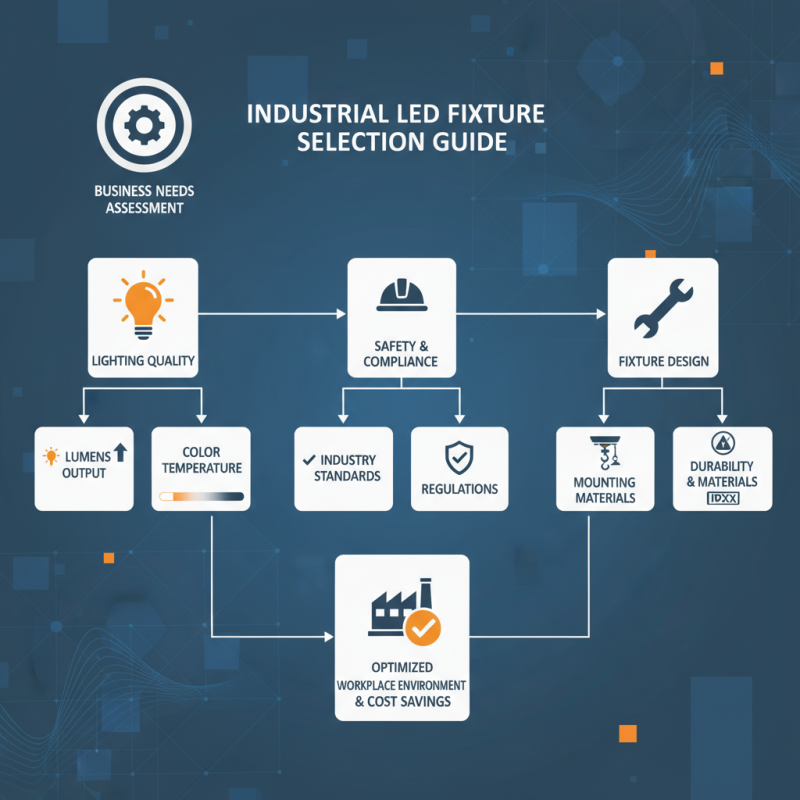

When evaluating various Industrial LED Fixtures, it’s essential to consider aspects such as lumens output, color temperature, and fixture design to match your specific business needs. Additionally, ensuring compliance with industry standards and regulations cannot be overlooked, as proper lighting not only boosts productivity but also enhances safety measures within the workspace. As we delve into this guide, we will explore the essential criteria to help you make informed decisions in selecting the best Industrial LED Fixtures tailored to your unique operational requirements.

Understanding Your Business Lighting Requirements

Understanding your business lighting requirements is crucial for selecting the best industrial LED fixtures. Different industries have unique lighting needs that can impact productivity, safety, and energy consumption. For instance, a report by the U.S. Department of Energy indicates that industrial facilities can save up to 60% in energy costs by upgrading to LED lighting compared to conventional lighting systems. This significant reduction underscores the importance of assessing your specific requirements before making a decision.

When evaluating lighting requirements, consider factors such as the type of work being performed, the necessary brightness levels, and the color temperature that enhances visibility. The Illuminating Engineering Society (IES) provides guidelines suggesting that manufacturing environments typically require around 100-300 foot-candles, while warehouses may need only 10-30 foot-candles. Additionally, incorporating smart lighting controls can further optimize energy use, adapting to real-time occupancy and daylight levels. Understanding these parameters ensures that your chosen LED fixtures not only meet the functional needs of your business but also provide cost-effective, long-term solutions.

Analyzing Business Lighting Requirements

Evaluating Different Types of Industrial LED Fixtures

When evaluating different types of industrial LED fixtures, it is essential first to consider the specific requirements of your business environment. There are various types, including high bay, low bay, and floodlights, each designed for particular applications. High bay fixtures are ideal for warehouses and large production areas due to their ability to provide bright, even illumination from significant heights. Conversely, low bay fixtures work well in spaces with lower ceilings, such as retail stores or small manufacturing facilities, ensuring that light reaches the work areas without casting harsh shadows.

Another critical factor to consider is energy efficiency and lumens output. Industrial LED fixtures vary in wattage, and selecting the appropriate wattage based on your lighting needs can significantly impact your energy costs. It is also important to look at color temperature; warmer temperatures may create a more inviting atmosphere, while cooler temperatures can enhance visibility and focus in work environments. Evaluating these aspects will aid in selecting the best industrial LED fixtures that not only meet regulatory requirements but also improve productivity and safety in your workplace.

Assessing Energy Efficiency and Cost Savings

When selecting industrial LED fixtures, understanding energy efficiency and potential cost savings is paramount. According to the U.S. Department of Energy, LED lighting can be up to 75% more energy-efficient than traditional incandescent lighting, significantly reducing power consumption which directly impacts operational costs. For businesses running extensive lighting systems, these savings can translate to thousands of dollars annually.

Furthermore, the initial investment in LED fixtures can be offset by their longevity and decreased maintenance requirements. Reports from the Lighting Research Center indicate that LEDs can last up to 50,000 hours, compared to just 1,000 hours for incandescent bulbs. This longevity means fewer replacements and reduced labor costs for maintenance.

In addition, companies that invest in high-efficiency LED systems may also qualify for energy rebates, enhancing their overall savings and supporting sustainability initiatives. By carefully choosing the right fixtures, businesses not only contribute to energy conservation but also enhance their bottom line in a competitive market.

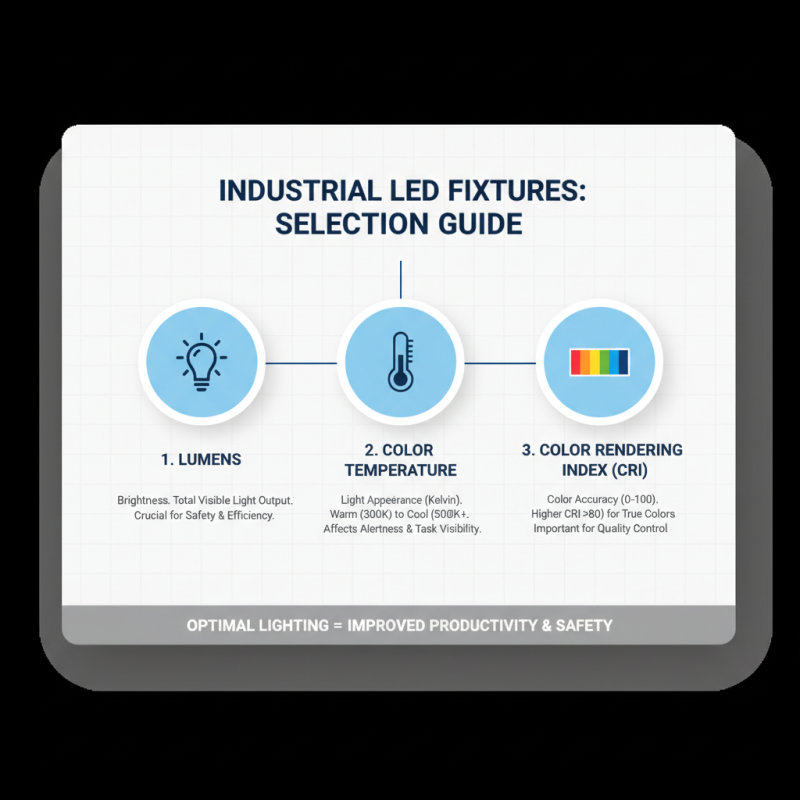

Comparing Lumens, Color Temperature, and CRI for Optimal Lighting

When selecting the best industrial LED fixtures for your business, paying attention to lumens, color temperature, and Color Rendering Index (CRI) is crucial for optimal lighting. Lumens measure the total amount of visible light emitted by a source, making them a key factor in determining the brightness of the fixtures. For industrial settings, adequate lumens are necessary to ensure safety and efficiency. Depending on the specific application, such as manufacturing or warehousing, a higher lumen output may be required to illuminate large spaces effectively.

Color temperature, measured in Kelvin (K), affects the mood and functionality of the workspace. Lower temperatures (around 3000K) produce a warm, inviting light, while higher temperatures (4500K to 6500K) yield a cooler, more energetic environment. Choosing the right color temperature can enhance productivity and worker comfort by aligning the lighting with the tasks performed. Additionally, CRI quantifies how accurately colors appear under artificial light. A CRI of 80 or above is generally considered sufficient for most industrial applications, ensuring that employees can accurately perceive colors, which is vital for quality control and safety inspections. Balancing these three factors will help you make an informed decision in selecting the right industrial LED fixtures for your business needs.

Choosing the Right Fixture Design for Your Environment

When selecting the right industrial LED fixtures, the environment in which they will be installed plays a crucial role in determining their effectiveness and efficiency. Factors such as ceiling height, room size, and the presence of obstacles must be carefully considered. For high-ceilinged warehouses, high-bay fixtures are essential to ensure adequate light reaches the ground. Conversely, for smaller spaces, low-profile fixtures may be more appropriate, providing sufficient illumination without overwhelming the area.

Additionally, the design of the fixture itself should align with the specific needs of the business environment. For instance, areas that require clean and sterile conditions, such as food processing plants or laboratories, benefit from fixtures that are resistant to dust and moisture. On the other hand, more decorative options may be suitable for showrooms or customer-facing spaces, where aesthetics play a vital role. By carefully analyzing these elements, businesses can enhance functionality while also creating a pleasant atmosphere that supports productivity and safety.

Related Posts

-

Unlocking Energy Efficiency in Manufacturing with Industrial Led Fixtures and Industry Insights

-

Unlocking Energy Efficiency with Innovative Commercial Led Fixtures for Global Buyers

-

Unlocking Energy Efficiency: The Future of Commercial LED Solutions for Global Buyers

-

5 Essential Tips for Choosing the Right Industrial Led Light Fixtures

-

7 Leading Industrial Led Fixtures to Illuminate Your Workspace

-

Mastering Best Industrial Led Lighting for Optimal Efficiency in Your Workplace